Food defense planning

The remainder of this guide will take you step by step through developing a food defense plan for your operation. When you are ready to begin, gather the following documents:

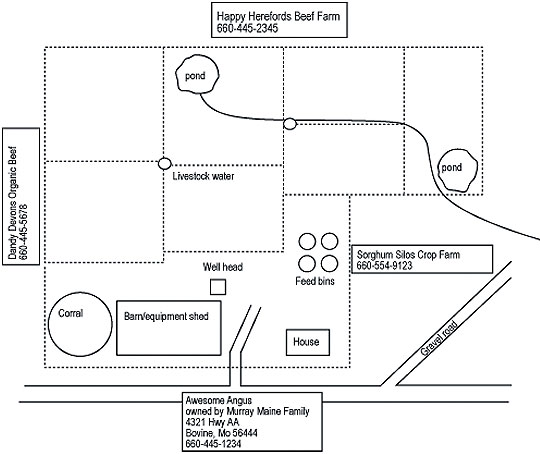

- A labeled map of the facility

- All written operational procedures, such as HACCP, GAP, BMP, GMP and SOPs

- Procedures related to your workforce, such as preemployment screening and security training

Supplemental publications are available to help ensure your team considers all of the important areas of your operation. We have found these three to be the most helpful (see the resource list for more information):

- Developing a Food Defense Plan for Meat and Poultry Slaughter and Processing Plants

- Guidance for Industry: Food Producers, Processors, and Transporters: Food Security Preventive Measures Guidance

- Pre-Harvest Security Guidelines and Checklist 2006

Samples of work sheets that will make this task easier are included. Blank work sheets for you to complete, remove and post, as appropriate, are in the appendix.

Store copies of the completed food defense and response plans in more than one secure location. Keep one copy on the operation’s premises and a second in a secure but accessible location outside of your operation, such as your home. Also consider saving a copy of your food defense plan online using a virtual document storage service.

Assess vulnerabilities

The first step in developing a food defense plan is to conduct a vulnerability assessment. Look for areas of your operation that are accessible to someone wanting to intentionally contaminate your product. To find the vulnerabilities in your operation, think like a disgruntled worker, member of a political group or anyone wanting to harm your business, cause illness or death, make a statement for a cause or disrupt the food supply chain. Consider the various people who have access to your operation; look for places where contamination would be easily distributed through normal operations, such as a feed or ingredient mixer where a contaminant could be added and mixed in; and identify critical areas that are not locked, as well as areas that are not visible to other employees or where access is not limited.

Assessing the vulnerabilities of your operation should not be a one-person job. Instead, put together a team made up of the owner or manager and other key personnel or family members who are familiar with most aspects of the operation. University extension personnel, your insurance agent, your county emergency manager or a member of the law enforcement community can also be included on the team.

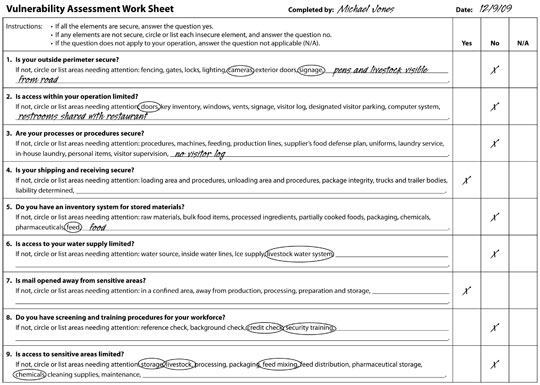

With the facility map and operational and workforce procedures on hand, the team should complete a Vulnerability Assessment Work Sheet. The team should consider the security of the listed elements and additional elements specific to your operation. Answer each question as follows:

- If all the elements are secure, answer the question yes.

- If any elements are not secure, circle or list each insecure element, and answer the question no.

- If the question does not apply to your operation, answer the question not applicable (N/A).

Only the questions that are answered no will need to be included in your food defense plan.

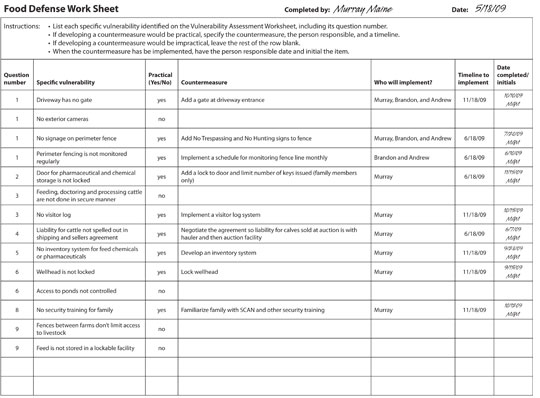

Write your food defense plan

Now that you have identified your operation’s vulnerabilities, it’s time to write your food defense plan. In the food defense plan, you will address each vulnerable element and determine whether a simple, practical and economical countermeasure could be implemented to make the element more secure. For each vulnerability you consider impractical to address, answer the practical question no, and move on to the next element. For each vulnerability you consider practical to address, write down a countermeasure and indicate who is responsible for implementing it and by what date. Once the countermeasure has been implemented, have the person responsible date and initial the plan.

In addition to your Vulnerability Assessment Work Sheet, it may be helpful to have your map and operational and workforce procedures available as you work through the Food Defense Work Sheet. Once you have completed the work sheet, you will have a food defense plan that can stand alone or be added to any HACCP or other plans you may have.

Developing countermeasures

Remember, the purpose of a food defense plan is to reduce the risk of intentional contamination in your operation. Countermeasures are actions you take to make vulnerable elements of your operation more secure. They protect your family, employees and customers; your product, reputation and livelihood; and your business, property and assets. The goal is to provide protection in the most economical ways possible.

As a general rule, procedural changes are the most economical. For example, checking references of potential employees is easy and inexpensive. Eligibility of new hires and validity of their Social Security numbers can be checked using the free E-Verify System.

The next most economical option may be technology. Will a technology such as dusk-to-dawn lighting or a lock reduce the risk of intentional contamination? If not, additional personnel may be needed, which is the least economical option.

Be freethinking and creative in countermeasure development, and keep in mind the three Ls suggested by the National Food Processors Association: light it, lock it, and limit access (Hollingsworth, 2002).

Marketing challenges

Once you have addressed the more obvious vulnerabilities and countermeasures, you need to deal with some of the challenges presented by marketing. The biggest challenge marketing pre-sents is assignment of liability, that is, determining who is responsible for protecting your livestock, produce or food product from contamination at each step along its way from your operation to the consumer’s table. For example, you need to determine who is liable for the livestock or food product while it is in transit or awaiting auction. Liabilities must be considered if you are:

- Niche marketing

For example, retained ownership cattle or organic grain. - Contract marketing

- Direct marketing

For example, farmers’ markets or retail outlets.

We recommend a two-pronged approach to liability, which we refer to as the double C’s: check and challenge.

Check your contract, whether oral or written, and negotiate the liability. The goal here is to make sure that you are liable only when the food is in your possession.

Check your contract, whether oral or written, and negotiate the liability. The goal here is to make sure that you are liable only when the food is in your possession.

Challenge those who might want to contaminate your product by making contamination more difficult with:

- Physical barriers

Add layers to your packaging, use tamper-resistant packaging, and lock the trailer while in transit. - Procedural barriers

W ork out transit details with your hauler that will reduce the risk to your cargo, and supervise visitors constantly during tours.

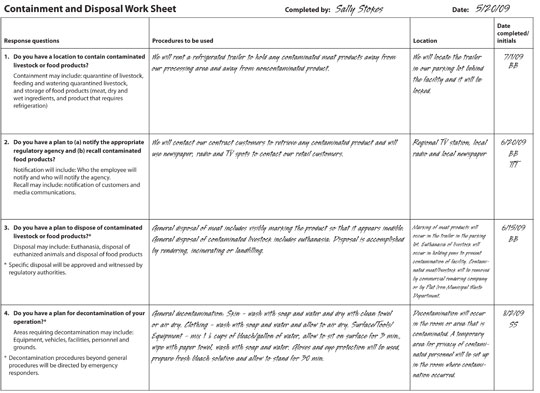

Prepare a response plan

The countermeasures you develop can reduce the risk of intentional contamination but cannot prevent it. You still need to prepare to deal with an intentional contamination incident so that, should one occur, you can quickly and efficiently contain the damage and get your operation back to normal production levels. Getting back into production as quickly as possible is key to keeping your business afloat.

As you begin to prepare your response plan, have your facility map on hand and as well as contact information for your suppliers, customers and local emergency responders. You may also need to refer to operational plans, such as such as HACCP, GAP, BMP and SOPs, which may contain information valuable to your response plan such as regulatory agency phone numbers, emergency protocols or recall plans.

To contain and minimize an emergency situation, understanding what needs to happen and in what order is critical. In the case of possible intentional contamination, the steps that need to be taken are containment, diagnosis, recall, and disposal. Each of these steps needs to be addressed in your response plan.

Containment

As soon as you suspect an intentional contamination, isolate all product or animals that may have been contaminated. In your plan, identify a location within your facility where potentially contaminated food or livestock can be quarantined separate from uncontaminated animals or products.

For a livestock operation, you will also need to plan how you will care for the animals while contained. The sample Containment and Disposal form poses questions designed to help with the processes and planning for handling contaminated or potentially contaminated livestock or food products.

Diagnosis

To respond to the emergency appropriately, you need to know what contaminant was used and how. As soon as possible, contact the appropriate person to diagnose the contaminant. If you have issues with livestock, the first call will be to your veterinarian, while a food processing plant will need to call a food inspector: FSIS for meat, poultry, eggs or catfish; FDA for other foods. In your plan, include a list of emergency telephone numbers. The numbers on the list will vary depending on your operation and its location.

Recall

Contaminated food or livestock that have already left the facility will need to be recalled and contained. To effectively recall your products, you must know where all of the food or livestock have gone. Keeping reliable contact information for your suppliers, customers and processing lots will make this much easier. Include their contact information in your plan. HACCP plans or similar operational documents will contain information related to trace forward/trace back, which is a requirement for food processors. Also, because recalls often result from contamination that has been unwittingly passed on to you by suppliers, you need to prepare for that possibility in your response plan.

Disposal

Contaminated livestock or food must not be allowed to enter the food chain, so your response plan must include a plan for disposal of contaminated livestock or food products and possible decontamination of your facility. The sample Containment and Disposal Work Sheet poses questions designed to help with the processes and planning for handling contaminated or potentially contaminated livestock or food products. Regulatory agencies such as FSIS or FDA are valuable sources to help determine what type of disposal will be needed and who will need to sign off on the plan before contaminated food can be disposed of.

For livestock, you will need to plan for euthanasia as well as disposal. Again, the methods used will depend on the type of contaminant involved and recommendations will be made by the veterinarian or emergency management official in charge. See the resource list for helpful publications on the quarantine and disposal of contaminated livestock or food.

Facility map

A map of your operation or facility will be vital to emergency responders in any situation. The map should provide contact information for the owner or operator of the facility and show the following:

- The facility in relationship to other properties, structures or environmental landmarks, such as streams

- Road access, transportation routes, perimeter boundaries and gates, including their dimensions

- Locations of utilities, septic and sewer systems

- Buildings, with doors and windows marked, and outbuildings, as well as building systems, such as ventilation, air conditioning and heating

Emergency phone list

The numbers on an emergency phone list will vary by location and type of operation, but in general should include the following categories:

- Emergency responders, including sheriff, highway patrol, police, fire, hospital and poison control

- Utilities, including electricity, water, phone and gas

- Regulatory groups, including FSIS for meat, poultry, eggs and catfish; FDA for other food; Animal and Plant Health Inspection Service (APHIS) for animals (the responding vet will likely start the chain of phone calls)

- Other state agencies, including your state’s Department of Health and Senior Services, Emergency Management Agency, and Department of Homeland Security

Supplier/customer phone list

To effectively respond to an emergency that is unfolding at a fast pace, maintain a list containing the names and contact information of all your suppliers and customers.

Employee emergency contacts

Maintain an emergency contact list for your employees that includes their phone numbers and addresses. Keep the list where it can be accessed quickly in an emergency.