Anaerobic lagoons — general information

Anaerobic lagoons are earthen containers sized to provide biological treatment and long-term animal waste storage. They are larger than manure storage basins, which do not provide significant biological treatment or long storage periods. On the other hand, anaerobic lagoons are smaller than aerobic lagoons, which are designed to provide a higher degree of treatment with less odor production. Anaerobic lagoons also decompose more organic matter per unit volume than aerobic ones.

Anaerobic lagoons are a useful size compromise between storage basins and aerobic lagoons. This guide will discuss anaerobic lagoon designs that meet the Missouri Department of Natural Resources (Missouri DNR) approval for dairy manure storage and treatment.

Anaerobic processes occur without free oxygen to liquefy or degrade high BOD (biochemical oxygen demand) organic wastes. Well-designed and managed lagoons have a musty odor. Foul odors indicate a malfunction. Do not use anaerobic lagoons where odors may be a nuisance.

Advantages of anaerobic lagoons:

- Allows manure to be handled hydraulically with flushing systems, sewer lines, pumps and irrigation systems.

- The high degree of stabilization reduces odors during land application.

- High nitrogen reduction minimizes the land area required for effluent disposal.

- Long-term storage is provided at low cost.

Disadvantages of anaerobic lagoons:

- Public perception may be that a lagoon is an "open container of manure."

- Undesirable odors may be produced during seasonal (spring and fall) changes due to "turnover" and spring start-up after the winter period of relatively little biological activity.

- Nitrogen availability is limited if manure is used as a fertilizer.

Location requirements

Ideally, lagoons should be located lower than the waste source so liquids can drain by gravity to the lagoon and/or wastes can be flushed to the lagoon by gravity. If wastes are scraped into the lagoon, close proximity to the source is especially important. If wastes are drained and/or flushed to the lagoon, close proximity for economical operation is not as crucial.

Missouri DNR requires lagoons to be 100 feet from a water supply used for human consumption and recommends 300 feet. If plans include a lagoon 100 to 300 feet from a water supply, a favorable report must be obtained from the Missouri Division of Geology and Land Survey. Also, the State Milk Board will not permit lagoons to be closer than 100 feet from the water supply on Grade A dairy farms.

Location with respect to non-owned residences is an important consideration. Minimum distances of 1/4 to 1/2 mile from property lines and non-owned residences have been suggested.

In some situations, especially in south Missouri, location may be dictated by soil and geological considerations.

Soil investigations

To economically construct a lagoon (without soil amendments, artificial liners or additional "hauled-in" clay soil), a suitable on-site clay soil is required. The ideal soil would have at least 30 percent fines content. Southwest Missouri block-structured red clay may not seal a lagoon, and a soil amendment, such as bentonite or soda ash, may be required to provide an acceptable seal. Natural Resources Conservation Service (NRCS) County Soil Surveys are a source of information during the preliminary screening for suitable sites. A soils investigation at a proposed lagoon site, done with a backhoe excavation or soil borings, is standard procedure in verifying a suitable location.

For a cost-shared lagoon, a soils investigation, performed by NRCS personnel or a soils consultant, is required. Only soils that fall within the Unified Soil Classification System designations below are accepted by DNR as suitable clay liners.

- CH

Clays of high plasticity - CL

Clays of low to medium plasticity — gravelly, sandy or silty clays - GC

Clayey gravels — gravel-sand-clay mixtures - SC

Clayey sands — sand-clay mixtures

Geological requirements

A geological report on the proposed lagoon site from Missouri DNR's Division of Geology and Land Survey is required. If the site is in an area with karst terrain and is rated as having a severe collapse potential, an earthen lagoon will not be approved.

Sites having severe geological limitations but a moderate or slight collapse rating may be reviewed on a case by case basis. Lagoons with artificial liners may be allowed at these sites. For sites having moderate geological limitations, a detailed soils investigation is required to determine the quantity and quality of the liner materials, the depth to bedrock and the depth to the seasonable high water table.

If the site evaluation indicates slight geological limitations, the above requirements may be waived and DNR may require density tests (permeability) be taken on the finished liner before approval for operation.

Additional soils specifications for lagoon liners are available in DNR's Publication 10 CSR 20-8.020, Design of Small Sewage Works.

Lagoon design — size

Anaerobic lagoons are sized by volume. Proper design or sizing of a lagoon ensures that sufficient volume is available for the required storage period. The recommended storage period, before the lagoon must be pumped down, is 365 days. The total volume of a lagoon is composed of several volume fractions:

Minimum design or permanent volume

This fraction provides sufficient dilution volume for the degradation of volatile solids by bacteria. This volume is not removed from the lagoon during pumpdown operations. The design volume may be reduced by 50 percent if a settling basin or solids separator is used to remove the solids.

Manure storage volume

This fraction provides storage for the manure volume the lagoon will receive; it is removed when the lagoon is pumped. Storage periods usually range from 6 to 12 months, with longer storage periods offering greater flexibility in scheduling pumping operations.

Run-off volume and other sources

This fraction provides storage for run-off plus any wash water or other fresh water used for cleaning buildings or lot areas. This volume also is removed from the lagoon during pumping operations.

Run-off from open concrete areas ranges from 2.77 feet per year in northwest Missouri to 4.17 feet per year in southeast Missouri. It is important to reduce the area draining directly into the lagoon to prevent unnecessary pumping. Surface water, unless needed for filling or dilution, should be diverted away from the lagoon. Volume components affected by rainfall (runoff volume and rainfall/evaporation volume) must be based on the wettest year in 10 years for Missouri DNR approval.

Net rainfall/evaporation on the lagoon surface and berm run-off

This fraction provides storage for the net gain of rainfall minus lagoon surface evaporation plus berm area run-off (inside the centerline). This volume is removed when the lagoon is pumped. For the wettest year out of 10 years, the rainfall minus evaporation varies from about 8 inches per year in northwest Missouri to 30 inches per year in southeast Missouri.

Similarly, dirt lot and the berm run-off varies from about 18 inches per year in northwest Missouri to 36 inches per year in southeast Missouri.

Sludge storage

Some fraction of the manure solids entering a lagoon remain as bottom sludge. Although the sludge buildup rate has not been defined, most standards suggest a volume allowance for sludge accumulation if sludge removal is not accomplished during lagoon pumping.

Current Missouri DNR guidelines do not require that volume be provided for sludge storage; however, such a provision may be advisable.

Freeboard

Freeboard in the range of one to three feet above full pool level is recommended.

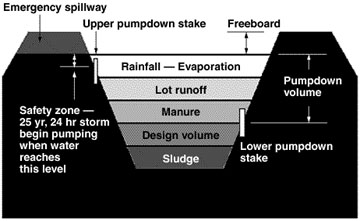

Figure 1 shows the volumes considered in the dairy lagoon design throughout Missouri. Surface area will vary with depth. A rough rule of thumb is one acre of surface area per 100 dairy cows.

Figure 1

Figure 1

Schematic of volume fractions in lagoon design.

Typical lagoon sizes for various herds are given in Table 1. These values are only averages and should not be used in lieu of a specific design. For more details on lagoon design, refer to Missouri DNR Manual 121.

Table 1

Typical sizes of dairy lagoons in Missouri

| Number of milking cows | Lagoon volume (cubic feet) | Depth (feet) | Waterline (feet x feet) | Pumpdown (volume, acre feet |

|---|---|---|---|---|

| 50 | 255,000 | 12 | 180 x 180 | 2.9 |

| 100 | 485,000 | 12 | 236 x 236 | 5.2 |

| 150 | 712,000 | 12 | 279 x 279 | 7.4 |

| 200 | 937,000 | 12 | 315 x 315 | 9.6 |

| 300 | 1,385,000 | 12 | 375 x 375 | 13.9 |

Lagoon design — geometry

Circular or square lagoons facilitate mixing and are usually more economical to construct. Rectangular lagoons may be used, but length to width ratios of 3:1 or less are recommended. Avoid narrow appendages isolated from the main body of water; they contribute little volume and may be a source of nuisance conditions.

Minimum depth should be 8 feet, although 8- to 20-foot depths are typical depending on animal numbers, run-off area, slope and underground geology. Deeper lagoons offer these advantages:

- A smaller surface area requiring less land.

- More thorough mixing of lagoon contents by rising gas bubbles.

- Minimum odors.

- Efficient use for mechanical aeration.

Earthen dike and bank slopes usually range from 2:1 to 3:1 with the recommended slope being 3:1 or less to facilitate establishment of vegetative cover and for safe mowing. A minimum 10-foot top width is recommended.

An emergency spillway should be provided at a minimum of one foot below the top of the berm after allowance is made for settlement. It should be located as close to natural ground as possible. The spillway is intended for dam protection only in the case of extreme flooding and is not to be used as a spillway in lieu of pumping down the lagoon.

Construction techniques — sealing

Proper lagoon construction will ensure groundwater resources are protected and the lagoon will perform as required during its useful life. The following steps are included in most guidelines for accepted construction techniques and methods for lagoons:

Site preparation

All trees, grass and organic matter should be removed from the site. Topsoil should be stockpiled adjacent to the construction site for later placement on the top and exposed slopes to enhance grass establishment. After stripping, the foundation area should be prepared to bond with the fill by removing loose, dry material; scarifying; disking; adjusting moisture; and compacting as necessary.

Cutoff trench

A cutoff trench may be required to remove sand, gravel or other water-conducting materials to prevent leakage under the embankment.

Excavation

Rocks, sand lenses, gravel and other materials not suitable for sealing should be removed from the impoundment. Excavation sufficient to obtain proper lagoon volume plus any required over-excavation for seal construction should be accomplished.

Embankments

Lagoon embankments should be constructed to allow for settling (usually five percent extra), mowing and preventing erosion. Suitable excavated materials free of sod, roots, frozen soil, stones more than 6 inches in diameter or other objectionable material should be used for fill. The minimum moisture content of the fill material and foundation should form a ball when kneaded by hand that will not easily separate. Experience has shown that with suitable soil material, three passes of a sheepsfoot roller per 6-inch fill lift on the embankment or bottom seal will provide adequate compaction for sealing.

Seal construction

Lagoons must have a seal on the bottom and sides sufficiently impermeable to protect groundwater. Seal construction guidelines generally call for over-excavation and recompaction of seal material in lifts not exceeding 6 inches compacted depth (not more than 9 inches deep before compaction).

The lower 6 inches of the bottom seal may be scarified and compacted in place to eliminate removal and replacement. The seal material should be within two percent below and four percent above the optimum moisture content for compaction. In general, a minimum of a 1-foot thick clay seal must be provided on the bottom and sides of a lagoon. The deeper the lagoon, the thicker the required seal, up to 4.63 feet thick for a water depth of 25 feet.

A given permeability or leach rate, such as 1 x 10-7 centimeters per second, is a typical seal construction specification. Soil amendments such as bentonite, soda ash or artificial liners may be required to obtain a proper seal. The lagoon seal should be covered with water immediately after construction to prevent drying and cracking (at least two feet above the highest bottom elevation).

Lagoon inlets

Inlets should be located near the center of the longest side of the lagoon, if possible, or at several locations in large lagoons. This allows the solids to be distributed and not allowed to accumulate near the edge. One discharge point per acre will avoid large concentrations of solids at one point and help minimize odors during spring warm-up. Multiple inlets should be fed equally from a distribution box.

If manure will enter the lagoon via a pipe or sewer line, the line should enter the lagoon below the minimum pumpdown level, or above the full pool level. This prevents ice from breaking the inlet pipe. The pipe should extend into the lagoon and have a minimum of 3 feet of liquid underneath it.

Inlets above the liquid surface are susceptible to freezing at the end if small dribbling flows are present. Also, cold air can move up the sewer line into the building if a trap is not provided. Pipe inlets below the minimum pumpdown level are generally preferred. Inlet pipes must be rigidly supported.

Submerged inlets carrying trickling flows with relatively high solid content are susceptible to plugging as solids accumulate or "float" where the lagoon water backs up into the pipe. Frequent flushing (at least once per day) eliminates this problem. Sewer lines with submerged discharges, carrying trickle flows into lagoons, should have a minimum of one foot of head above the maximum lagoon level for each 100 feet of run. All sewer lines should be designed with clean outs at 50-foot intervals.

Solids exclusion — agitation

Bedding and fibrous material will break down very slowly, or not at all, in a lagoon. It is recommended this material be excluded from the lagoon if at all possible. Non-degradable material leads to excessive sludge buildup and/or crusts forming on the lagoon, both of which interfere with pumping operations.

Agitation during pumpdown should be considered as a means of reducing sludge buildup. Sludge removal may be justified if sludge levels build to a significant percentage of total lagoon volume. Although a somewhat difficult operation, regular sludge removal can extend the life of a lagoon virtually indefinitely.

Start-up/management

Proper lagoon design and construction are fruitless if the lagoon is not properly managed. Many problems associated with lagoons can be solved with proper management.

Lagoons should be filled one-third to one-half full with water before manure is introduced into the lagoon. This will assure sufficient dilution is available for the establishment of bacterial activity. This will also minimize start-up odors. Starting a lagoon in the late spring or early summer months will establish a bacterial population before cold weather and will help prevent excessive odors the following spring.

Lagoons perform best when they are loaded continuously. Therefore, a waste management system should be devised that loads the lagoon at least weekly, and preferably daily. Flushing systems provide ideal loading conditions for lagoons.

Pumping and irrigating from the lagoon is the single most important management item. In addition to preventing overflow and the associated pollution potential, pumping removes dissolved and suspended solids and allows room for the addition of dilution water through rainfall or other means.

If lagoons are not pumped and diluted, salt concentrations may increase to levels that can inhibit bacterial activity. Salt levels in mature lagoons should be monitored yearly to ensure they remain at safe levels. Electrical conductivity (E.C.) is a convenient field measurement that indicates salt content. E.C. levels above 10,000 micro mhos per centimeter indicate probable decreased bacterial activity, solids buildup and increased odor.

Pumping operations should be initiated before the lagoon is full to assure space (safety volume) is always available to hold the 25-year, 24-hour storm (6 inches in Missouri). Missouri DNR guidelines call for pumping the lagoon when the water level is 1 foot or more below the full pool level if designed for 365-day storage. If the open-lot surface area contributing to the lagoon inflow is greater than 70 percent of the lagoon area, the safety volume depth is computed using the following formula:

| Safety volume depth = | 0.67 + | square feet lot surface x 0.5 feet square feet lagoon water surface |

Permanent markers should be installed at that depth to initiate pumping the lagoon (1 foot or more below full pool level) and at the lagoon design level to indicate when to stop pumping.

Recycling lagoon effluent for flushing

Intakes for recycle pumps are frequently floated about two feet below the surface to minimize disturbing the surface crust or pumping sludge. The pump intake should be located remote from the waste inlet. A wet well should be considered as a convenience for installing and servicing the recycle pump.

Safety and appearance

Efforts should be made to make a lagoon as aesthetically pleasing as possible. Berms and embankments should have a good grass cover for appearance and erosion control and be mowed and maintained on a regular basis.

Such practices enhance access to all lagoon areas and improve appearance. If a lagoon is within public view, a row of trees will help hide the view. A well-maintained lagoon is less likely to attract attention and cause controversy than a lagoon with an offensive appearance.

A fence should be provided to prevent access of children, trespassers and livestock. Post warning signs (SEWAGE TREATMENT FACILITY — KEEP OUT) and keep the gate locked.

References

- ASAE Engineering Practice: ASAE EP403.1 Design of Anaerobic Lagoons for Animal Waste Management. ASAE Standards, 1991. St. Joseph, Michigan.

- Rules of the Department of Natural Resources, Division 20 — Design of Small Sewage Works. Chapter 8, Design Guidelines, 10 CSR 20-8.020. 1989. Clean Water Commission, Missouri Department of Natural Resources, Jefferson City, Mo. 65102.

- Natural Resources Conservation Service, Missouri Specifications, USDA/NRCS, Columbia, Mo. 65201.

- Agricultural Waste Management Field Manual, U.S. Department of Agriculture, August 1975, revised March 1983.

- Pollution Control for Agriculture, R.C. Loehr, 1977. See page 376, Table A-19, Composition of Animal Waste.

- Proceedings of the Fifth International Symposium on Agricultural Wastes, 1985, Available Nutrients in Livestock Waste, pages 295-305.

- Animal Waste Composting with Carbonaceous Material, EPA-600/2-78-154, U.S. Environmental Protection Agency, September 1978.