The safe and proper storage of pesticide is a component of good management. A correctly designed and maintained pesticide storage site is essential. Whether maintaining small amounts of pesticide in a locked cabinet or large inventories in sophisticated chemical holding facilities, a suitable storage site

- Protects people and animals from accidental exposure

- Protects the environment from accidental contamination

- Prevents damage to pesticides from temperature extremes and excess moisture

- Protects the pesticides from theft, vandalism, and unauthorized use

- Reduces the likelihood of liability.

The purpose of this guide is to address the guidelines that will help ensure the safe and environmentally friendly storage of pesticide products.

Site

Pesticide storage facilities must be located away from human and livestock habitat. Ideally, a facility should be built as a separate structure dedicated for pesticide storage. If a separate facility is not possible, a precise area within an existing building should be specified for pesticide storage. The storage site must not be in an area known to flood and should be situated so that runoff from spills and leaks cannot contaminate water sources. The storage site should be situated at least 100 feet away from sensitive areas such as wellheads.

Managers of large commercial facilities should consider the prevailing wind, proximity of surrounding commercial and residential areas, potential fire hazard and the availability of emergency response services.

Secure the site

Keeping out unauthorized people is an important function of the storage site. No matter how small or large the facility, keep it securely locked. Post legible signs on doors and windows to alert people that pesticides are stored there. The signs should clearly state, "DANGER PESTICIDES - KEEP OUT." "No smoking" signs should also be posted (Figure 1).

Figure 1

Figure 1

Post warning signs where pesticides are stored.

Labeling statements

Typical pesticide labeling storage instructions include:

- Store at temperatures above 32 degrees Fahrenheit.

- Do not contaminate feed, foodstuffs or drinking water during storage.

- Store in original container only.

- Do not store near ignition sources such as electrical sparks, flames or heated surfaces.

- Flammable. Do not use, pour, spill or store near heat or open flame. Do not cut or weld container.

Prevent water damage

Water from burst pipes, spills, overflows, excess rain or irrigation, or flooding streams can damage pesticide containers and pesticides. Water or excess moisture can cause

- Metal containers to rust

- Paper and cardboard containers to split or crumble

- Pesticide labeling to peel, smear, run or otherwise become unreadable

- Dry pesticides to clump, degrade or dissolve

- Slow-release products to release their pesticide

- Pesticides to move away from the storage site.

If the storage site is not protected from the weather or if it tends to be damp, consider placing metal, cardboard and paper containers in sturdy plastic bags or cans for protection. Large metal containers, which may rust when damp, and dry pesticides in paper sacks, which may cake when damp, can be placed on pallets within the storage site (Figure 2).

Figure 2

Figure 2

Store sacks of dry pesticide on pallets.

Control the temperature

The storage site should be indoors, whenever possible. Choose a cool, well-ventilated room or building that is insulated or temperature-controlled to prevent freezing or overheating (Figure 3). The temperature range normally recommended for liquid pesticides is 40 to 100 degrees Fahrenheit. The pesticide label may provide more specific temperature information for the product. Freezing temperatures can cause glass, metal and plastic containers to break. Excessive heat can cause plastic containers to melt, glass containers to explode and some pesticides to volatilize and drift away from the storage site. Another adverse effect of temperature extremes is that the potency of the pesticide can be destroyed.

Figure 3

Figure 3

A modulating temperature control unit keeps a storage area at an ideal temperature.

Provide adequate lighting

The storage site should be well lighted (Figure 4). Pesticide handlers using the facility must be able to see well enough to

- Read pesticide container labeling,

- Notice whether containers are leaking, corroding or otherwise disintegrating

- Clean up spills or leaks completely

Figure 4

Figure 4

Provide adequate lighting in storage area.

Use nonporous materials

The floor of the storage site should be made of sealed cement, glazed ceramic tile, no-wax sheet flooring, or another easily cleaned material (Figure 5). Carpeting, wood, soil and other absorbent floors are difficult or impossible to decontaminate in case of a leak or spill. For ease of cleanup, shelving and pallets should be made of nonabsorbent materials such as plastic or metal. If wood or fiberboard materials are used, they should be coated or covered with plastic or a polyurethane or epoxy paint.

Figure 5

Figure 5

Use nonporous material for storage area flooring.

Maintain the storage site

Store only pesticides, pesticide containers, pesticide equipment and a spill cleanup kit at the storage site. Do not keep food, drinks, tobacco, feed, medical or veterinary supplies or medications, seeds, or personal protective equipment — other than equipment necessary for emergency response — at the site. These items could be contaminated by vapors, dusts, or spills and cause accidental exposure to people or animals.

Keep pesticide containers securely closed whenever they are being stored. Tightly closed containers help protect against

- Spills

- Cross-contamination with other stored products

- Evaporation of liquid pesticides or solvents

- Clumping or caking of dry pesticides in humid conditions

- Dust, dirt and other contaminants getting into the pesticide, causing it to be unusable.

Take precautions to prevent cross-contamination of your pesticides. If liquid and dry pesticides are stored in close proximity, store the dry formulations above the liquid pesticides in case of a spill or leak. Each class of pesticide should be stored in its own area. For example, keep herbicides apart from insecticides and fungicides. If possible, store volatile products separately. Some formulations of 2,4-D should be stored away from other types of pesticides because of volatility loss. Vapors from opened containers of these products can move into other nearby pesticides and chemicals and make them useless. The labeling of volatile herbicides usually will direct you to store them separately from seeds, fertilizers and other types of pesticides.

Store pesticide containers with the label in plain sight. Costly errors can result if the wrong pesticide is chosen by mistake. Labels should always be legible. They may be damaged or destroyed by exposure to moisture, dripping pesticide, diluents or dirt. You can use transparent tape or a coating of lacquer or polyurethane to protect the label. If the label is destroyed or damaged, request a replacement from the pesticide dealer or the pesticide manufacturer immediately.

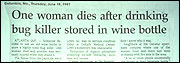

Store pesticides in their original containers. Never put pesticides in containers that might cause children and other people to mistake them for food or drink. You are legally responsible if someone or something is injured by pesticides you have placed in unlabeled or unsuitable containers (Figure 6).

Figure 6

Figure 6

Store pesticides in their original containers.

Isolate waste products. If you have pesticides and pesticide containers that are being held for disposal, store them in a special section of the storage site (Figure 7). Accidental use of pesticides meant for disposal can be a costly mistake.

Figure 7

Figure 7

Isolate waste products for disposal.

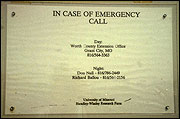

Keep an up-to-date inventory of the pesticides you have in storage. Each time a pesticide is added to or removed from the storage site, update the inventory list. The list will help you keep track of your stock and will be essential in a fire or flood emergency. The inventory list also will aid in insurance settlements and in estimating future pesticide needs. Other useful pieces of information to keep on hand are the product labels, material safety data sheets, a building floor plan showing the exact location of the pesticides and emergency telephone numbers (Figure 8).

Figure 8

Figure 8

Clearly post emergency information.

The shelf life of pesticides is variable. Some have a relatively short shelf life and cannot be carried over from year to year. Mark each container with the date of purchase before it is stored. Use older materials first. Whenever possible, purchase only the quantities of pesticides required for a single season to minimize the need for off-season storage. If the product has a shelf life listed in the labeling, the purchase date will indicate whether it is still usable. Excessive clumping, poor suspension, layering or abnormal coloration may be indications that the pesticide has broken down. If you have doubts about the shelf life of a pesticide, call the dealer or manufacturer for advice.

Safety tips for the storage facility

- Store protective equipment and clothing in a nearby location that provides immediate access but is away from pesticides and their fumes, dusts or possible spills (Figure 9). Provide an immediate supply of clean water and have an eyewash dispenser immediately available for emergencies (Figure 10). Soap and a first aid kit are also necessary.

- Establish procedures to control, contain and clean up spills. Familiarize everyone with the procedures and provide tools and absorbent materials to clean up spills (Figure 11). Prevent pesticide fires. Some pesticides are highly flammable; others do not catch fire easily. The labeling of the pesticides that require extra precautions often will contain a warning statement in the "Physical and Chemical Hazards" section or the "Storage and Disposal" section.

- Install fire detection systems in large storage sites and equip each storage site with a working fire extinguisher that is approved for all types of fires, including chemical fires.

- If you store highly toxic pesticides or large amounts of any pesticides, inform your local fire department, hospital, public health officials and police of the location of your pesticide storage facility before a fire emergency occurs.

- Tell fire department officials what types of pesticides are regularly stored at the site. Give them a floor plan, and work with them to develop an emergency response plan.

Figure 9

Figure 9

Store protective equipment and clothing nearby.

Figure 10

Figure 10

Have clean water, an eyewash dispenser, soap and a first aid kit available for emergencies.

Figure 11

Figure 11

Provide tools and absorbent material to clean up spills.

Pesticide storage checklist

Safety is the key element in proper pesticide storage. Use this checklist as a guide for your facility. If you answer no to any of the statements below, you should consider making corrections.

General information

Yes No — Pesticide storage site has clean and neat appearance

Yes No — Current, on-site pesticide inventory

Yes No — Emergency telephone numbers are posted

Pesticide containers

Yes No — Containers marked with purchase date

Yes No — Insecticides, herbicides and fungicides are segregated

Yes No — Pesticides are stored in original containers

Yes No — Labels are legible and attached to containers

Yes No — Container caps are tightly closed

Yes No — Bags are tightly sealed

Yes No — No reused pesticide containers present

Yes No — Pesticides are stored off of floor and low to ground

Yes No — No liquid products are stored above dry products

Yes No — Feed is stored separately from pesticides

Yes No — Used containers are rinsed and punctured

Yes No — Rinsed and unrinsed containers are separated

Spills and disposal

Yes No — Storage area is free of spills and leaks

Yes No — Shovel and absorbent materials are on hand

Yes No — Floor drains are sealed (if present)

Safety information

Yes No — No smoking sign is posted

Yes No — "Pesticides. Keep Out." is posted at entrance to storage site

Yes No — Safety equipment is separated from pesticides

Yes No — Fire extinguisher is in good working order

Yes No — Storage room is locked

Yes No — Storage site is well lit and ventilated