At first glance, the idea of generating methane gas has considerable merit because it appears to offer at least a partial solution to two pressing problems — the environmental crisis and the energy shortage. Unfortunately, present-day large-scale methane generation requires rather high investments in money and management, which considerably reduces the idea's practicality. This guide is intended to provide quantitative information so that the feasibility of methane generation can be evaluated for a given situation.

Anaerobic process

Livestock manure contains a portion of volatile (organic) solids, which are fats, carbohydrates, proteins and other nutrients that are available as food and energy for the growth and reproduction of anaerobic bacteria.

The anaerobic digestion process occurs in two stages. The volatile solids in manure are initially broken down to a series of fatty acids. This step is called the acid-forming stage and is carried out by a particular group of bacteria, called acid formers. In the second stage, a highly specialized group of bacteria, called methane formers, convert the acids to methane gas and carbon dioxide.

The anaerobic process depends on methane formers because they are more environmentally sensitive than acid formers. Methane bacteria are strict anaerobes and cannot tolerate oxygen in their environment. They function best at 95 degrees Fahrenheit; therefore to obtain maximum gas production, heat usually must be added to a digester.

Methane bacteria are slower growing than acid-forming bacteria and are extremely pH-sensitive (pH 6.8-7.4 optimum). The acid formers will grow rapidly if an excess of organic material is fed to a digester, producing an excess of volatile acids. The accumulated acids will lower the pH, inhibiting the methane bacteria and stopping gas production. To help buffer the system against increases in acids, high alkalinity must be maintained. Lime has been added to digesters during start-up or periods of slug loading to maintain pH control.

A variety of materials can become toxic to anaerobic bacteria — salts, heavy metals, ammonia and antibiotics. Bacteria require minimum amounts of salts for optimum growth. However, if salts are allowed to accumulate beyond bacterial requirements, they can become toxic and inhibit digestion.

Soluble heavy metals (copper, zinc, nickel) may be toxic to digester bacteria. Most heavy metals can be precipitated out with sulfides and will cause no problems in the sludge. Livestock feeds containing significant amounts of heavy metals may require special attention.

Most livestock manure (particularly swine and poultry) contain appreciable amounts of nitrogen, which will be converted to ammonia in the digester. Most of the ammonia will accumulate in the digester material and will become toxic if not controlled. Ammonia toxicity is a major concern in the anaerobic digestion of livestock manure. To avoid the problem, loading rates must be carefully controlled.

Methane production potential

The immediate and obvious benefit from methane production is the energy value of the gas itself. Hence, the question most frequently asked concerning the process is: "How much gas will I get?" The answer to this question depends on several factors that determine the efficiency of the operation.

In the anaerobic process, a certain amount of gas is produced per pound of volatile solids broken down or destroyed by the bacteria. This is referred to as "gas yield." Average values are given for the various animal species in Table 1. During digestion, only a fraction of the volatile solids contained in the raw manure are broken down or destroyed by the bacteria. Average percentages for volatile solids break-down for different animal species are also given in Table 1.

Table 1. Potential gas production of swine, dairy, poultry and beef manure (68 degrees Fahrenheit, atmospheric pressure).

| Swine (150 pounds) | Dairy (1,200 pounds) | Poultry (4 pound bird) | Beef (1,000 pounds) | |

|---|---|---|---|---|

| Gas yield, cubic feet per pound volatile solids destroyed | 12 | 7.7 | 8.6 | 15 |

| Volatile solids voided, pounds per day | 0.7 | 9.5 | 0.044 | 5 |

| Percent reduction of volatile solids | 49 | 31 | 56 | 41 |

| Potential gas production cubic feet per animal unit per day | 4.1 | 22.7 | 0.21 | 31 |

| Energy production rate, Btu per hour per animal | 103 | 568 | 5.25 | 775 |

| Available energy Btu per hour (after heating digester) | 70 | 380 | 3.5 | 520 |

If the weight of volatile solids produced by an animal or bird per day is estimated, the potential gas production for each species on a daily basis can be calculated. For example, a 150-pound hog will produce about 0.7 pound volatile solids per day. Of this, 49 percent (or 0.34 pounds) is broken down by bacteria. Since about 12 cubic feet of gas per pound of volatile solids is produced by bacteria, a 150-pound hog has the potential to produce about 4.1 cubic feet of gas per day. These data are also summarized in Table 1 for each species.

The gas obtained in anaerobic digestion of animal wastes is a mixture of carbon dioxide and methane with trace amounts of hydrogen sulfide and hydrogen gas. Typically, the mixture is composed of about 60 percent methane and 40 percent carbon dioxide regardless of the type of waste. Pure methane has heat value of about 1,000 Btu per cubic foot, so we can expect the methane-carbon dioxide mixture to have a heat value of about 600 Btu per cubic foot. Heat value data for the various species on "per hour" basis is given in Table 1. Typically about one-third of the energy in the manure gas is needed to maintain the necessary 95 degree F temperature in the digester. Hence the energy available for other uses is two-thirds of the total energy produced. These values are listed in the last row of Table 1.

To be meaningful, these heat values must be compared with some typical heat requirements that might logically use the gas as an energy source. Table 2 lists several typical farm heat requirements that could possibly use manure gas as an energy source and the numbers of the various animals needed to supply energy at the required rate. Obviously, the best possibilities for using manure gas are the various heating requirements associated with the home.

Table 2. A comparison of some typical farm heat requirements and the number of animals needed to meet these requirements.

| Heat requirement (Btu per hour) | Swine (150 pounds) | Dairy (1,200 pounds) | Poultry (4 pound bird) | Beef (1,000 pounds) | |

|---|---|---|---|---|---|

| Kitchen range1 | 65,000 | 77 | 14 | 1,547 | 11 |

| Water heater2 | 45,000 | 107 | 20 | 2,143 | 15 |

| Refrigerator3 | 3,000 | 22 | 4 | 429 | 3 |

| Heat 1,500 square foot home4 | 37,500 | 535 | 99 | 10,714 | 72 |

| In-bin grain drying heater5 | 2 million | 14,285 | 2,631 | 285,714 | 1,923 |

| 50 hp tractor operating at full load6 | 637,000 | 4,550 | 838 | 91,000 | 612 |

| 1. Assumed to operate 2 hours per day, i.e., 24-hr average of 5,417 Btu per hour 2. Assumed to operate 4 hours per day, 24-hr average = 7,500 Btu per hour 3. Assumed to operate 12 hours per day, 24-hr average = 1,500 Btu per hour 4. Assumed 25 Btu per hour per square foot heat requirement 5. Assumed to operate 12 hours per day during drying season, 24-hr average = 1 million Btu per hour 6. Assumed to operate 12 hours per day, 24-hr average = 318,500 Btu per hour |

High-energy requirements such as grain dryers and tractors are not compatible with methane generators because of the numbers of animals required. It should be noted that most farm heat requirements are seasonal and the problem of how to best use the gas in the "off" season exists. Storage of the gas is one possibility and will be discussed later.

Data presented in Tables 1 and 2 were generated entirely from laboratory experiments. In many cases there is a considerable loss in efficiency when such an operation is conducted in a large-scale field situation. For example, in calculating the potential gas production per animal it was assumed that all the volatile solids voided by the animal were introduced into the digester. In the practical situation, a portion of the volatile solids will likely be lost en route to the digester. Perhaps a more significant loss would be the degradation of a portion of the volatile solids between the time of excretion and introduction into the digester. Such losses indicate the need for an efficient manure handling system that continuously feeds manure into the digester. It is possible that the gas production values listed in Table 1 could be decreased by as much as 50 percent, depending on the efficiency of the system.

Design and equipment

The design volume of an anaerobic digester is sized according to the amount of volatile solids that must be treated daily and the period of time the material remains in the digester (detention time). Loading rates are normally expressed in pounds of volatile solids (#VS) per cubic foot of digester volume. Loading rates and detention times for various livestock are presented in Table 3. The loading rates as listed in Table 3 are designed to maintain the necessary bacterial balance and prevent ammonia toxicity from occurring.

Table 3

Loading rates, detention time and digester volume for swine, dairy, poultry and beef

The primary structure consists of a digestion tank, usually cylindrical in shape to promote better mixing. Most tanks are constructed of concrete and must be strong enough to withstand the weight and pressures of the contained liquid. The bottom is generally cone-shaped to facilitate sludge removal. The top can be fixed or floating. A floating top provides expandable gas storage with pressure control but costs more and is more difficult to manage. Regardless of the tank shape or top used, the structure must be airtight. Methane gas when mixed with oxygen is highly explosive. Most tanks are set at least partially below ground level. This helps support the structure and provides some insulation. That portion of the tank above ground may have to be insulated to minimize heat losses.

Mixing aids digestion by continually bringing the bacteria in contact with the waste material and by distributing the heat more uniformly. Mixing can be accomplished by:

- Recirculating the gas collected from the top of the tank

- Mechanical mixers. Gas recirculation does a better job of mixing but equipment costs are higher.

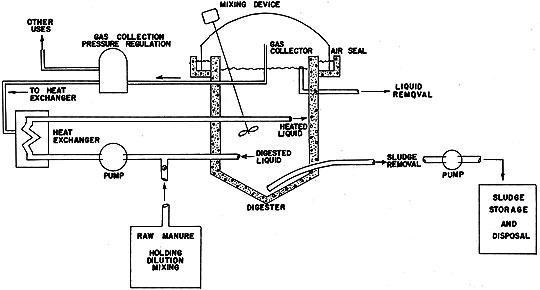

Heat may be added by circulating the digester material through an external heat exchanger as shown in Figure 1 or by pumping heated water through a heat-exchange coil inside the digester (not shown). External heat exchangers are difficult to use because of the corrosive nature of the digester liquid. The special, non-corrosive materials required are expensive and the heated water approach is normally used.

Pumping of digester contents and sludge removal will necessitate using special solids (sludge) handling pumps. All piping must be of sufficient size to prevent clogging.

To use the methane gas as an energy source requires some gas collection and pressure regulation equipment, including the necessary safety devices to prevent explosions.

Digester management

A digester must be loaded with manure on a regular basis to ensure a continuous supply of food for the anaerobic bacteria. Manure collection from the livestock production facility and feeding to the digester should be done at least once daily. Intermittent or slug loading of manure can cause acid build-up, upsetting the bacterial balance and reducing gas production. Once the bacterial populations are disrupted, several months may be required to stabilize them.

A manure slurry of the proper solids content is required to maintain correct loading rates and detention times and to facilitate mixing and pumping. Loading rates given in Table 3 result in solids content of 2 to 10 percent in the feed material. Depending on the livestock enterprise and manure collection systems, some method of diluting and mixing the raw manure must be incorporated into the manure-handling system.

Sustained performance of an anaerobic digester depends heavily on proper management of the chemical and physical environment within the digester. The contents of the digester should be monitored at regular intervals. The best indicators of digester imbalance are:

- Decreasing gas production

- Decreasing pH

- Decreasing methane/carbon dioxide ratio

- Increase in volatile acids.

Imbalance in the system may be due to a change in temperature, loading rate or nature of the waste. The addition of toxic materials such as antibiotics can also cause unbalance.

When an unbalanced condition is discovered, maintain pH control until the cause of the upset is discovered. The pH can be controlled by reducing the feed to the digester and/or adding lime. If the feed is reduced, the waste flow from the production facilities will have to be handled in an alternative manner.

Management of digester gas

Even with energy shortages, problems exist with how to best handle or use gas generated from manure. Basically two things can be done: store the gas as it is produced or burn the gas as it is produced to fulfill some energy requirement. In reality, a practical system would involve a combination of the two, but for purposes of discussion we will consider them separately.

Methane, unlike propane, does not liquefy under reasonable pressures and temperatures. While propane can be liquefied at pressures in the 130 to 250 psi range at ambient temperatures, methane does not liquefy at any pressure if the temperature is greater than -116 degrees Fahrenheit. Fuel contains the greatest heat value per unit volume when in liquid form. Methane has a relatively low heat value per unit volume because it does not liquefy at normal storage pressures and ambient temperatures.

For example, assume that we wanted to store two months' accumulation of gas from a 500-head swine methane generation unit. From Table 1, we see that this amounts to 70 Btus per hour. x 720 hours per month x 2 months = 100,800 Btus per hog. At 600 Btus per cubic feet. this amounts to 168 cubic feet per hog, or 84,000 cubic feet for 500 hogs. If the methane is compressed at 5500 psi, a 224-cubic-foot storage tank would be required 3 feet in diameter by 32 feet long.

By comparison, an equal number of Btu (energy) is contained in 548 gallons of propane. This would require a tank only 3 feet in diameter and 10 feet long at a pressure (130 to 250 psi) much less than that of the methane. Another important factor is the strength required in the walls of a tank in which gas is stored at very high pressures. For pressures greater than about 1000 psi, storage tanks more than a foot or so in diameter must have extra wall thickness, which makes such storage impractical.

Because of the relatively low heat value of methane (compared to propane and other liquid fuels) and its difficulty to liquefy under reasonable pressures, methane is impractical to store in large amounts. Hence most storage applications would likely involve only short-term accumulations of methane.

The other obvious alternative to storage of methane is to use it as it is generated. The easiest way to accomplish this is to burn the gas as it flows from the digester. Obviously this isn't efficient use of the gas unless the flame is used to fulfill a heat requirement. The most frequently proposed use is home heating with the methane gas.

From Table 2, notice that 535 hogs would be required to heat a 1,500 square foot home and almost 800 hogs would be required to fulfill the heating, water heating, cooking range and refrigeration demands of a typical home. This illustrates that it may be feasible to use methane to some extent in fulfilling the energy demands of the household. Such demands are seasonal, however, and gas use in the off-season remains a problem. For reasons already mentioned, storing off-season (summer) gas until winter probably is not feasible.

Energy demands of grain dryers and tractors are high enough that using methane is not practical. Because of the relatively low heat value of methane, tremendous volumes are required to fulfill such demands. Most livestock operations simply do not have sufficient numbers of animals available to meet those demands.

An alternative often proposed that would solve the seasonal problems of heating energy demands involves the burning of methane in an internal combustion engine. The engine in turn drives an alternating current generator, which supplies power to the farmstead electrical system. With proper regulating and controlling equipment, this power could be used to its maximum availability, and at the same time power supplier electricity need would be proportionately reduced. However, in such a scheme there is a significant energy loss in converting energy from the gas form to the electrical form. Internal combustion engines are about 25 percent efficient and generators are about 85 percent efficient.

Consider, for example, a 500-hog production facility that would yield about 103 Btu per hog per hour (Table 1). In this example, we are using the higher Btu production rate (103 as opposed to 70) because excess heat from the engine coolant can be used to heat the digester. For 500 hogs producing energy at the rate of 103 Btus per hour, we have a total energy production of 51,500 Btus per hour. If we were able to convert this energy directly into electricity with 100 percent efficiency, we would have about 15 kilowatts of power, or about 15 horse power. However, since our total efficiency is only 0.25 x 0.85 = 0.21 we will realize only 51,500 Btus per hour. x 0.21 = 10,815 Btus per hour. or about 3.2 kilowatts of electrical power from the original 15 kilowatt equivalent. Hence the advantages this system offers in eliminating seasonal energy demands may be offset by the heavy loss in efficiency in converting the energy from gas to electricity.

Efficient management and use of digester gas will continue to be a problem. Research is needed to investigate more efficient methods of energy conversion and methods of concentrating the energy in methane gas to eliminate storage difficulties.

Digesters as waste management components

The above discussion has been concerned with the energy aspects of anaerobic digestion. A digester will also be an integral part of the waste management system. The advantages and disadvantages should be reviewed from a waste management viewpoint.

A primary advantage of an anaerobic digester is its ability to nearly completely stabilize raw manure. As a result, the effluent from a properly operating digester is relatively odor-free and odor problems usually associated with production facilities and disposal operations may be reduced.

Another advantage of anaerobic digestion is nearly complete retention of the fertilizer nutrients (N,P,K) that were in the raw manure. Nutrient losses may occur in subsequent handling of the effluent. This advantage may become more significant in the future if fertilizer shortages become more acute.

Another advantage of the anaerobic digester is its ability to stabilize more waste per unit volume than other treatment facilities such as lagoons. This advantage is offset in most cases by the fact that a lagoon will probably be required for storage of digester effluent until such time that it can be used in irrigation or otherwise distributed over the land.

This brings up the point that a digester is not a complete disposal tool in itself. The volume of liquid effluent from a digester is the same as the liquid volume of waste introduced into the digester. Hence there is no reduction in liquid volume of waste to be handled due to the action of the digester. The digester does reduce the amount of solids to be handled and provides relatively odor-free treatment.

Digester effluent is not suitable for discharge into streams. There usually are less expensive systems that conform with the pollution regulations set forth by the Missouri Clean Water Commission.

Summary

Some energy can be extracted from manure through anaerobic digestion. But this would likely comprise only a small fraction of the total energy needs of a typical farm. High investments in money and management along with difficulties in efficiently using methane make anaerobic digestion a questionable venture for most farmers.

If energy and fertilizer shortages become more acute and pollution regulations concerning odor become more strict, methane generation may become a feasible process in waste management systems. Research is needed to reduce capital costs of methane generation systems and provide techniques for proper management of such systems.