Well location

Whether a well taps water just below the ground or hundreds of feet deep, its location on top of the ground is a crucial safety factor. Locating a well in a safe place takes careful planning and considering factors such as where the well is in relation to surface drainage and groundwater flow. A well downhill from a livestock yard, a leaking tank or a septic system runs a greater risk of contamination than a well on the uphill side of these pollution sources.

Surface slope does not always indicate the direction a pollutant might flow once it gets into the ground. In shallow aquifers, groundwater flow often is in the same direction as surface-water flow. If the aquifer supplying water to your farmstead well is deep below the surface, however, its slope may be different than that of the land surface. Finding out about groundwater movement on your farm may require special monitoring equipment.

Separation distances

Many states encourage appropriate well location by requiring minimum separation distances from sources of potential pollution, thus using the natural protection provided by soil. However, state well codes may not mention some farmstead activities and structures. When no distances are specified, provide as much separation as possible between your well and any potential contamination source, especially if your farmstead is on highly permeable soils or thin soil overlying limestone bedrock or if the contamination source or activity presents a high risk of contamination.

Minimum separation distances regulate new well installation. Existing wells are required by law only to meet separation requirements in effect at the time of well construction. Make every effort, however, to exceed old requirements, and strive to meet current regulations (Table 1).

Both soil and slope can make placing a well tricky business. Keep in mind that separation distances required by the state are minimums. You may choose greater separation distances in some cases, depending on factors at your site. This will assure you that your well will not be polluted by farmstead activities in the future. Also consider contamination sources on adjacent properties.

Changing the location of your well in relation to contamination sources may protect your water supply, but it will not protect the groundwater itself.

Any condition likely to cause groundwater contamination should be improved, even if your well is far away from the potential source. Whether or not drinking water is affected, groundwater contamination is a violation of Missouri law.

Simply separating your well from a contamination source may reduce the chance of pollution, but it does not guarantee that the well will be safe. Storm water and groundwater can carry bacteria, oil products and pesticides from one place to another. Wells located in the path of polluted water run a risk of contamination from overland flow washing into an improperly sealed well. Some wells become contaminated through polluted recharge at great distances, depending on the depth of the aquifer and the well intake.

Table 1

Minimum separation distances between well and potential farmstead sources of contamination for new well installation.

| Feet from well | Source |

|---|---|

| 50 | Septic tank |

| Mixing pesticides | |

| 75 | Silage storage and transfer tube (plastic) |

| Silage storage earthen pit or trench | |

| 100 | Feed storage facility, glass-lined |

| Silo with pit | |

| Silo without pit, but with concrete floor and drain | |

| Liquid waste-disposal system | |

| Manure stack | |

| Manure storage structure, earthen or excavated | |

| Manure storage structure, fabricated, liquid-tight | |

| Soil-absorption field (less than 8,000 gallons per day) | |

| Filter strip | |

| Animal barn pen with concrete floor | |

| Sewage-holding tank | |

| Animal shelter or yard | |

| Manure hopper or reception tank, liquid-tight | |

| Non-potable well | |

| Cistern | |

| Wastewater adsorption fields | |

| Wastewater lagoons | |

| 300 | Gasoline and other liquid-petroleum products Underground Surface (more than 1,500 gallons) |

| Fuel-oil tanks Underground Surface (more than 1,500 gallons) | |

| Pesticide or fertilizer storage tank (more than 1,500 gallons) |

For sources not addressed: Provide as much separation as possible from well. These are distances in the well code. Local waste storage ordinances may require different storage distances. Source: RSMo 256.600 Missouri Private-Well Construction Standards — Rules and Organizational Structure. Dec. 1993

Well construction

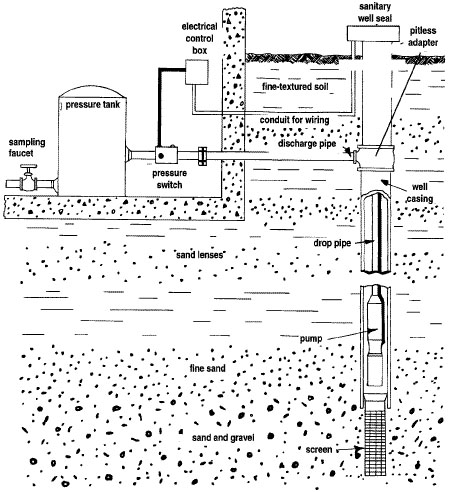

Poor well design can cause contaminated groundwater to enter the well by allowing rain or snowmelt to reach the water table without filtering through soil. Wells located in pits, or without grout or a cap, allow surface water to carry bacteria, pesticides, fertilizer or oil products into your drinking-water supply. Proper well design reduces the risk of pollution by sealing the well from anything that might enter it from the surface (Figure 1).

The way in which a well was constructed, even if the design is sound, affects its ability to keep out contaminants. Several things you should check are described in the following sections. Information about well construction may be available from the person who drilled your well, from the previous owner or from the well-construction report. Construction reports also may be available from the Department of Natural Resources (DNR), Geological Survey Division, in Rolla, Mo. This overview of well construction and inspection can help you understand your drinking-water contamination-risk ranking. For more information, contact a registered well driller or pump installer. Your DNR regional office can help interpret private well regulations in the Revised Missouri Statutes (RSMo 256.600).

Figure 1

Figure 1

Typical domestic well installation with discharge pipe extending into the home. Adapted from Planning Your Well: Guidelines for Safe, Dependable Drinking Water, University of Illinois-Champaign Cooperative Extension Service, December 1988.

Casing and well cap

During construction, the well driller installs a steel or plastic pipe, called casing, to prevent collapse of the borehole. The space between the casing and the sides of the hole provides a direct channel for surface water and pollutants to reach the water table. To seal off that channel, the driller fills the space with grout — such as cement, concrete or a special type of clay called bentonite — depending on the geologic materials encountered. Both grout and casing prevent pollutants from seeping into the well.

Visually, you can inspect the condition of your well casing for holes or cracks at the surface or down the inside of the casing with a light. If you can move the casing around by pushing against it, your well casing may be unable to keep out contaminants. In areas of shallow fractured bedrock less than 20 feet from surface, check on the condition of your well casing by listening for water running down into the well. The pump should not be running. If you do hear water, the casing could have a crack or hole, or you are not cased down to the water level in the well. Either situation is risky.

To prevent contaminants from flowing down inside the well casing, the driller installs a tight-fitting, vermin-proof well cap to prevent easy removal by children and entry by insects or surface water. Install the cap firmly with a screened vent incorporated into it so air can enter the well. Check the well cap to see that it is in place and tightly secured. Wiring should be in the conduit. If your well has a vent, be sure that it faces the ground, is tightly connected to the well cap or seal and is properly screened to keep insects out. The well code requires a vermin-proof cap or seal for all private wells. (Not all wells have caps. Some may have pumping equipment attached at the surface.

Casing depth and height

The depth of casing required by the state private-well code for your well depends on the nature of the subsurface geologic materials. The casing requirements vary throughout the state because of Missouri's varied geology. Your regional DNR office can advise you on these minimum requirements. Meeting minimum well codes does not, however, guarantee a safe water supply; you may want to exceed minimum casing depth.

Wells cased below the water level can afford greater protection from contamination. Well casing extending at least 30 feet below the water level can ensure that surface water is filtered through soil and geologic materials before entering the well. Wells cased more deeply provide greater sanitary protection but also can result in aesthetic water problems caused by dissolved solids, such as hardness and iron. Typically, the casing extends one foot to two feet above surrounding land, preventing surface water from running down the casing or on top of the cap and into the well. The private-well code requires that at least 12 inches of casing pipe extend above the final grade of the land.

Well age

Well age is an important factor in predicting the likelihood of high nitrate concentrations. A well built more than 70 years ago is likely to be at the center of the farmstead; it may be shallow and is probably surrounded by many potential contamination sources. Older well pumps are more likely to leak lubricating oils, which can get into the well. Older wells also are more likely to have thinner casing that is corroded. Even wells with modern casing that are 30 years to 40 years old are subject to corrosion and perforation. If you have an older well, you may want to have a district or county health department sanitarian or a qualified well driller inspect it.

Well types

Bored or dug wells

Bored or dug wells pose the highest risk of allowing drinking-water supply contamination because they are shallow and often poorly protected from surface water. A bored or dug well is a large-diameter hole, usually more than 2 feet wide, which often is constructed by a large diameter drill or by hand.

Driven-point (sand-point) wells

Driven-point (sand-point) wells, which pose a moderate-to-high risk, are built by driving assembled lengths of pipe into the ground. These wells typically are smaller in diameter — 2 inches or less — and less than 50 feet deep. They only can be installed in areas of relatively loose soils, such as sand.

Drilled wells

All other types of wells, including those constructed by a combination of jetting and driving, are drilled wells. Drilled wells for farm use are commonly 4 inches to 8 inches in diameter. All bedrock wells must be at least 6 inches in diameter.

Managing and maintaining existing wells

Well depth

Shallow wells draw from the groundwater nearest the land surface, which may be directly affected by farmstead activities. Depending on how deeply the well casing extends below the water table, rain and surface water soak into the soil and may carry pollutants.

Local geologic conditions determine how long it takes for this to happen. In some places, this process happens quickly — in weeks, days or even hours. Areas with thin soil over fractured bedrock or sand and gravel aquifers are particularly vulnerable. Even a site with thick sand over fractured bedrock is vulnerable to contamination.

On the other hand, thick clay soils don't allow contaminants to reach the water table. They may prevent contamination or delay the day when a well turns bad. If you have a deep well (more than several hundred feet below the water table), the groundwater supplying the well may have traveled a considerable distance underground over a long time, offering greater protection to the well.

You wouldn't let a tractor run too long without an oil change. Your well deserves the same attention. Good maintenance means:

- Testing the water twice a year;

- Keeping the well area clean and accessible;

- Keeping pollutants as far away as possible;

- Periodically having a qualified well driller or pump installer check the well mechanics.

Better management of your existing well

Existing wells most likely were put where they are because of traditional practice or regulations in place at the time of construction. Although these wells are legal, consider how well yours conforms to current standards, which incorporate new knowledge about groundwater contamination and well water. You can find these standards in the state private-well regulations (RSMo 256.600).

You might want to move activities such as pesticide mixing, tank rinsing or gasoline storage farther from your well. You might want to upgrade wells, get rid of well pits, install caps or extend casings.

Changing the location of other practices, such as a silo or livestock yard, may prove expensive. Until you can meet minimum-separation distance requirements, change the way you manage such structures to control contaminants.

If your silo is too close to your well, for example, you may want to install a system for collecting any juices draining from freshly ensiled forage. You can install concrete curbs to direct livestock yard runoff away from the well. Short-term manure stacks are another example, posing a risk of well contamination by bacteria or nitrates. Place them on clay soil or, better yet, a concrete slab to reduce the chance of polluting your drinking water. Also, protect them from rain.

Other management changes to consider include moving traffic areas and chemical or gasoline storage areas away from the well and upgrading or better managing your septic system.

Backflow prevention

Backflow or backsiphoning from pesticide mixing tanks allows chemicals to flow back into the well through the hose. Use an anti-backflow device when filling pesticide sprayer tanks to prevent the chemical mixture from flowing back into the well and contaminating groundwater. You may find inexpensive anti-backflow devices for hoses that are used to fill farm sprayers from irrigation or spray-equipment suppliers. If you don't have such a device, keep the hose out of the tank when filling the pesticide sprayer.

Consider buying an inexpensive plastic nurse tank. A nurse tank is filled with water at the well and then used to fill the sprayer away from the farmstead and away from the well. For more information about preventing well contamination from pesticide mixing and loading practices, see MU publication WQ676 Reducing the Risk of Groundwater Contamination by Improving Pesticide Storage and Handling.

You must report all backsiphons and spills to the Missouri Department of Natural Resources Emergency Response Hotline. To report, and to receive advice and help with backsiphonage, call the 24-hour emergency hotline at 573-634-2436.

You also should consider anti-backflow devices on all faucets with hose connections, or maintain air gaps between hoses or faucets and the water level. Otherwise, you risk having contaminated water from laundry tubs, sinks, washing machines, pressure washers, outside hydrants and swimming pools flow back through plumbing to contaminate your water supply.

Water supplies that have cross-connections between them — connections between two otherwise separate pipe systems, such as potable and non-potable — also put your drinking water at risk.

Water testing

Keep an eye on water quality in existing wells by testing it twice a year. Although you cannot have your water tested for every pollutant, some basic tests indicate whether or not problems exist.

At a minimum, test your water annually for bacteria and nitrate. Where the well draws from sandy materials or granite bedrock, test once for corrosiveness. Good initial tests for a private well also include tests for hardness, alkalinity, pH, conductivity and chloride.

In addition, you may conduct a broad scan of your water for a number of contaminants. Some mail-in labs offer a screening for metals, inorganic chemicals, volatile organic chemicals, herbicides/pesticides and coliform bacteria for $80 to $120 per chemical.

The results may not include contaminants that could be near your farm, such as the most commonly used pesticides in your area. Test for contaminants that most likely will be found at your farmstead. Test for lead if you have lead pipes or soldered copper joints. Test for volatile organic chemicals (VOCs) if they have been used nearby or if there has been a spill of oil, petroleum or solvent. Although testing for pesticides can be costly, the expense may be justified if:

- Your well has nitrate levels of more than 10 milligrams per liter (mg per liter) (reported as nitrate-nitrogen, NO3-N) or 45 milligrams per liter (reported as nitrate, NO3);

- A pesticide spill has occurred near the well, or backsiphonage has occurred; or

- Your well is shallow, has less than 15 feet of casing below the water table or is located in sandy soil and downslope from irrigated croplands where pesticides are used.

For $70 or more, commercial labs test your drinking-water supply for atrazine and other pesticides.

You can seek more advice on appropriate tests to run from your local MU Extension center, health department or DNR regional office.

You should test your water more frequently if:

- Your family experiences unexplained illnesses;

- Anyone in your family is pregnant;

- You notice changes in livestock or poultry performance;

- Your neighbors find a particular contaminant in their water;

- You note a change in water taste, odor, color or clarity;

- You have a spill or backsiphonage of chemicals or petroleum products near your well or on your farmstead;

- You apply chemicals, manure or whey to your fields within 100 feet of your well; or

- Your livestock operation inspectors require it.

You can have your water tested by both public and private laboratories. A list of certified labs is available from the Missouri Department of Natural Resources (DNR) and the Missouri Department of Health and Senior Services.

Follow the lab's instructions for water sampling to ensure accuracy of results.

Use only the container provided, and return samples promptly. Bacteria sample bottles are sterile and must be returned within specified time limits.

Because many materials, including bacteria and nitrate-nitrogen, are present naturally in minor amounts in groundwater or can vary seasonally, contact a specialist for help in interpreting test results.

Bacteria and nitrates are two important indicators. At excessive levels, they can cause health problems themselves and also may suggest problems with the well's location or construction. Hardness and pH indicate how corrosive the water may be to your plumbing system.

The chloride level also may indicate other problems. In Missouri, most chloride comes from such human activities as road salts and waste disposal.

In most areas of Missouri, a level of more than 10 milligrams per liter suggests that land use is somehow affecting your well.

Keep in mind that activities off your farm can affect your groundwater. Chemical spills, changes in land use and the presence of landfills increase the chance of pollutants getting into your water. If your water has a high nitrate or bacteria level, talk with a specialist about the need for additional testing.

It is important to record the results and to note changes in water quality over time. In addition to water-analysis test results, keep records of a few other things to tell what is happening with your water system. These include well-construction details and dates and results of maintenance intervals for the well and pump.

Well maintenance

Every 10 years to 20 years, your well may need mechanical attention from a qualified well driller or pump installer. Follow these maintenance practices:

- Do not use gasoline or lawn and agricultural chemicals near your well.

- Do not mix pesticides, rinse sprayer equipment or discard empty pesticide containers near your well.

- Protect wells from household wastewater treatment systems that may back up.

New wells

New wells are expensive but they can be a good investment for the future. Getting the most from such an investment means placing the well away from contamination sources and working to maintain the quality of the well. Some simple principles for new well construction include:

- Follow the state's recommended minimum separation distances. The Missouri private well construction regulations (RSMo 256.600) contains these separation distances and other requirements for drinking-water wells. A full listing also is available from your local MU Extension office, a certified well driller or the DNR.

- Place your well on ground higher than surrounding pollution sources, such as fuel tanks, livestock yards, septic systems or pesticide mixing areas. Where practical, place the well as far as possible from pollution sources, but no closer than the minimum separation distances in RSMo 256.600.

- If necessary, build soil up around the well so that all surface water drains away from it.

- Avoid areas that are prone to flooding.

- Groundwater flow generally follows surface drainage patterns. Unless you know the exact direction of groundwater flow on your property, place the well so that pollution sources are between the well and the nearest creek, river or lake. Groundwater generally flows from upland areas and discharges in a body of surface water. In all cases, place your well on ground higher than surrounding pollution sources such as fuel tanks, livestock yards or pesticide mixing areas.

- Make the well accessible for pump repair, cleaning, testing and inspection.

- Hire a competent, licensed well driller and pump installer. Be sure the driller disinfects the well with chlorine after construction,tests the water for bacteria after drilling (as required by state law) and provides detailed information about the well's depth and construction.

Unused wells

Many farms have unused wells. No one knows how many of these wells exist in Missouri, although estimates range in the hundreds of thousands.

If not properly filled and sealed, these wells can provide a direct conduit for surface water carrying pollutants to groundwater without filtering through soil, or they can allow contaminant movement from one aquifer to another.

Hire a licensed, registered well driller or pump installer to close these wells. Effective well plugging calls for experience with well construction materials and methods as well as a working knowledge of the geology of the well site. You may, however, do your own well-abandonment work. You don't need a license, but you must meet the minimum well-code requirements when you abandon and fill a well.

You often need special equipment to remove old pumps and piping and to install sealing material inside the well. Use of inappropriate materials and methods can lead to well settling, collapse and continued groundwater contamination. If plugging materials are improperly installed in a well, you'll find patching up defective work is nearly impossible.

The most obvious places to find unused wells are where pipes stick out of the ground around the farmstead, in an area where a farmstead used to be or under an old windmill. You may not know the history of your property, however, and unused well locations may not be obvious. A depression in the ground may indicate an old well. Also, wells often were drilled in house basements, under front steps or near old cisterns.

State well regulations (RSMo 256.600) require reports of well plugging. These regulations also explain well-closing requirements:

- Remove pump, piping and any other obstructions from the well.

- Close the entire length of unused wells with slurries of cement or clay.

- Chlorinate the well before sealing it. Seal the entire length of the well to prevent surface water from entering the groundwater and to prevent contamination movement from one aquifer to another.

The goal of proper sealing is to restore as closely as possible the geologic conditions that existed before the well was built. For specific requirements, consult the Missouri Geological Survey Division, Missouri Department of Natural Resources in Rolla, Mo., at 573-368-2165.

Proper well closing takes time and money. Costs vary with the well depth, diameter and geology of the area. Spending a few hundred dollars plugging an unused well near your home may prevent contamination of your drinking water.

A method of well closure that may be less expensive was approved in February 1990. Chipped bentonite products may now be used to fill wells and drillholes.

More information on this topic and related topics is available from the Missouri Department of Natural Resources, Geological Survey Division, https://dnr.mo.gov/geology/; MU Extension, 205 Agricultural Engineering Building, Columbia, Mo., 65211, 573-882-0085, extension.missouri.edu; and the Natural Resources Conservation Service office https://www.nrcs.usda.gov/wps/portal/nrcs/site/mo/home/.

Resources

A list of certified well-water testing laboratories is available from the Missouri Department of Natural Resources, Geological Survey Division, P.O. Box 250, Rolla, Mo. 65401, 573-354-1752, https://dnr.mo.gov/geology/.

Local MU Extension offices or the regional DNR offices listed below can help interpret well results:

- Kansas City

816-251-0700 - Northeast (Macon)

660-385-8000 - Southeast (Poplar Bluff)

573-840-9750 - Southwest (Springfield)

417-891-4300 - St. Louis

314-416-2960

For more information about drinking water quality standards, contact:

- U.S. Environmental Protection Agency Safe Drinking-Water Hotline

800-426-4791 - Missouri Department of Natural Resources (DNR), Geological Survey Division

573-368-2165 - Missouri Department of Health and Senior Services, State Public Health Laboratory

573-751-3334

For help locating possible sources of contamination, contact qualified plumbers, well drillers, pump installers, MU Extension regional specialists, DNR regional offices listed above or district and county health department sanitarians. Besides locating contamination sources, they also can recommend improvements.

For well construction or inspection, contact DNR regional offices (listed above) or registered well drillers or pump installers.

For well abandonment issues, consult:

- Your regional DNR office or your local MU Extension center

- Revised Missouri Statutes well-driller regulations (RSMo 256.600) are available online

For copies of well construction reports filed with the state, contact the state Geological Survey Division, Wellhead Online Services, at https://dnr.mo.gov/mowells/. Provide the legal description (county, township, range, section and quarter section) of the well's location. If your farm covers more than one section, make a note of that in case well drillers reported the wrong section. If known, provide the year the well was installed and the owner's name at the time.

For more information on contamination, testing and interpretation, contact the U.S. Environmental Protection Agency, Drinking Water Management Branch, 11201 Renner Blvd., Lenexa, Kan.; 913-551-7003 or the Safe Drinking Water Hotline, 800-426-4791